Working principle of belt Juicer

Time:2021-04-07 09:14 Browse:277

Vegetable and fruit juicer is widely used in the dehydration and drying of plant roots, stems, leaves and fruits (including wine residue and beer residue). Cassava pomace, sweet potato pomace, corn pomace, bagasse, Chinese medicine pomace, apple pomace, Pear Pomace, pineapple pomace, tea pomace, wood pulp fiber, pulp fiber, horseshoe dust, soybean pomace, potato pomace, coffee pomace, inner surface pomace, pulp material and mechanical filtration dehydration.

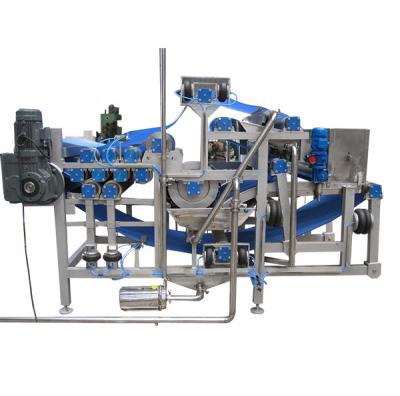

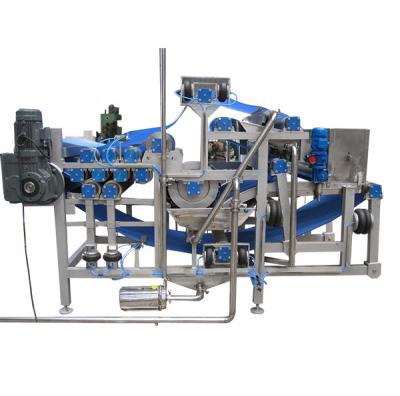

Working principle of belt Juicer

The main engine consists of frame, upper and lower transmission shafts, reducer assembly, pressure filter belt, cleaning belt assembly, feeding assembly, distribution device, fastening device, belt correction assembly, pressurization device, protection device, pneumatic electrical control device, cleaning water filter device, etc. The supporting equipment includes water filtering device (including arc net filter and water storage tank), stainless steel vertical multi-stage pump, water spray reflux pump, etc. The refined raw materials (solid-liquid mixture) are continuously pumped into the hopper by screw pump (the occupied bandwidth of materials is adjustable), and the distribution rollers are evenly distributed. In the downward curved wedge area, a large amount of water is slowly pressed out to form an extruded filter cake. In the press area, a drum with an "L" belt presses the water out and ensures that the water quickly overflows from both sides.

The filter belt is made of nylon warp and weft, which has the characteristics of acid and alkali resistance, food hygiene, convenient juice production, no water absorption and high strength. When working, the air bag is used to tighten the pressure filter belt and the special valve is used to control the deviation of the belt, which is not only stable but also avoid overload, reliable and realizes the whole process automation.