How does apricot core beating machine work?

Time:2021-04-07 09:23 Browse:277

The juicing, beating and jam making of apricot are very popular in food industry in recent two years. As we all know, fruit beating should be classified. Fruits can be divided into two types: nucleated and seedless. For example, apples, peaches, mangoes and apricots are classified as nucleated fruits; bananas, oranges and kiwifruit are classified as seedless fruits.

In the food industry, seedless fruit is relatively simple for juicing and beating, but how to beat seeded fruit?

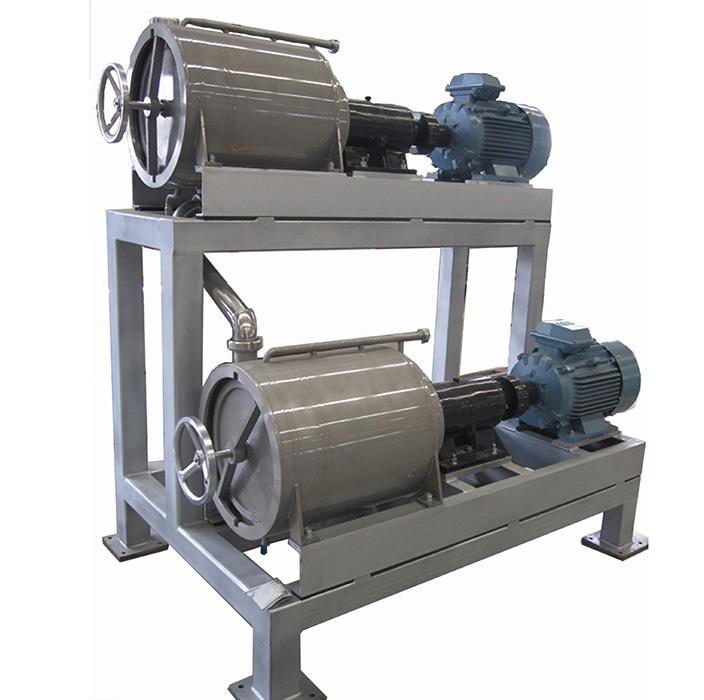

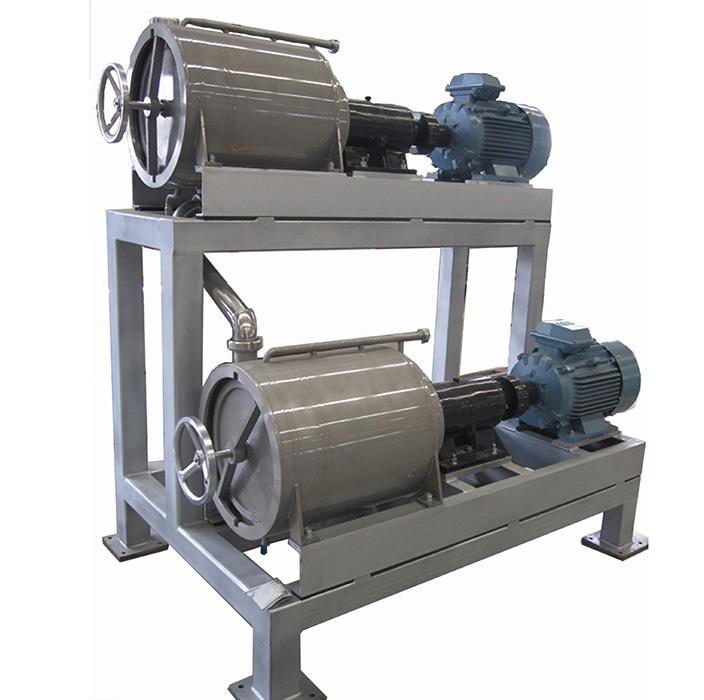

Apricot seedless beating machine is suitable for beating fruits and vegetables such as berries and nuts. Its characteristics: pulp juice, slag (skin, seed, kernel) active separation; can be combined in the production line for flow shop, and can be produced as a single machine. All the places that touch the materials are made of 304 stainless steel and excellent edible rubber. They have good corrosion resistance and won't pollute the materials to ensure food hygiene.

When apricot seedless beating machine is used for beating stone fruit, the first rotor adopts the equipment of removing core rod, which can remove core, and the flesh flows into the next cylinder, and the beating is completed by scraper rotor.

The beating principle of Xingzi Jingjiang Weineng mechanical de nucleation beating machine: the motor is driven by a triangle belt, which makes the rotor parts rotate at high speed. The fruit enters the machine from the feeding port, and the material is spirally transported to the de nucleation rod by the feeding blade. Under the effect of de nucleation rod, the material is smashed. Because of the effect of centrifugal force, the juice and meat (already pulpy) in the material will enter the next process through the sieve hole on the screen, and the core will be discharged from the slag outlet by the slag pulp leaf, and then the pulp and slag will be separated actively. When the pulp enters into the secondary cylinder, the pulp plate evenly discharges the material between the scraper and the screen. Because of the reverse effect of the scraper and the existence of the lead angle, the material moves along the cylinder to the outlet end. The moving track is spiral. The material is crushed by centrifugal force during the moving process between the scraper and the screen, and the juice and meat (which has become pulp) pass through the screen hole After entering the next process, the skin and seeds are discharged from the slag hopper, and then reach the intention of active separation.