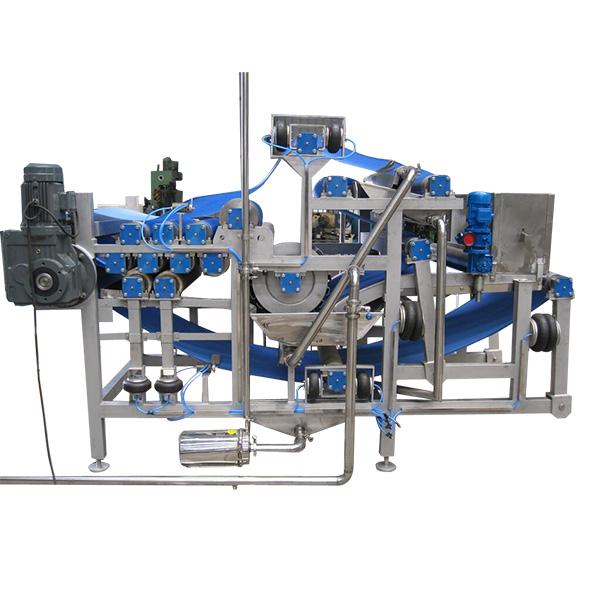

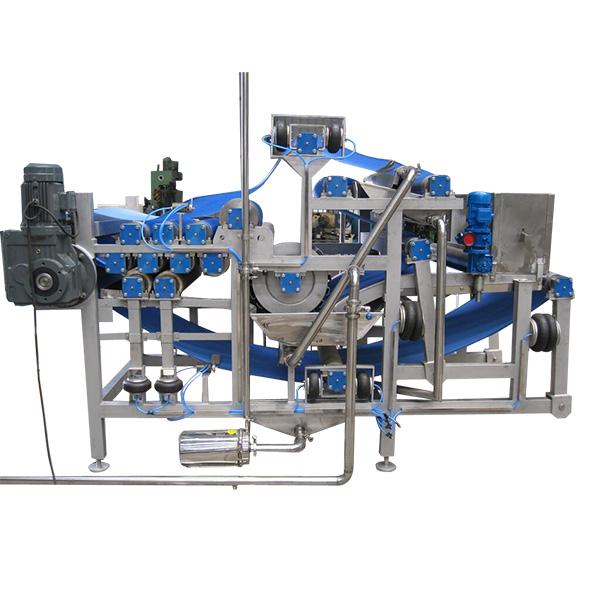

Technological process of belt filter press

Time:2021-04-07 10:04 Browse:277

Fruit juicer is needed for fruit juicing, so in fruit juicer, there are many different kinds of juicer equipment. Among them, belt juicer and belt filter

press are also a new type of juicing equipment which are very easy to use in recent years. The process of juice extraction by Jingjiang Weineng

mechanical belt filter press is divided into four steps

press are also a new type of juicing equipment which are very easy to use in recent years. The process of juice extraction by Jingjiang Weineng

mechanical belt filter press is divided into four steps

1. First juice: fresh fruit juice just sent out from the crusher enters the crusher by pushing the speed regulating screw pump. At this time, most

of the separated juice has been automatically discharged by gravity.

2. Low pressure extraction area: the pulp moves forward between the two filter belts, and then is transported by a large roller with an L-shaped

strip on the surface. There is a certain pressure between the two filter belts. In this low pressure area, juice is produced outward and inward by

the press roller.

strip on the surface. There is a certain pressure between the two filter belts. In this low pressure area, juice is produced outward and inward by

the press roller.

3. High pressure extraction area: the pulp cake between the filter belts is continuously extracted by the press roll in the "s" shaped winding

piece, and the press roll gradually decreases, and the pressure gradually increases. At last, there is a press roll on one side of the second

stage press roll, which is pushed upward by the push force of the air bag to press the juice to the maximum extent.

piece, and the press roll gradually decreases, and the pressure gradually increases. At last, there is a press roll on one side of the second

stage press roll, which is pushed upward by the push force of the air bag to press the juice to the maximum extent.

4. After the juice is squeezed by high pressure, the fruit residue is discharged by the slag removing and scraping device. (in order to improve

the scraping effect and facilitate the cleaning of the belt, the user can choose to add a brush to further brush the residue). Finally, the belt is

automatically cleaned by the cleaning mechanism.

the scraping effect and facilitate the cleaning of the belt, the user can choose to add a brush to further brush the residue). Finally, the belt is

automatically cleaned by the cleaning mechanism.