Structure description and improvement direction of squirrel

Time:2021-04-07 11:38 Browse:277

1. Structure of squirrel cage crusher

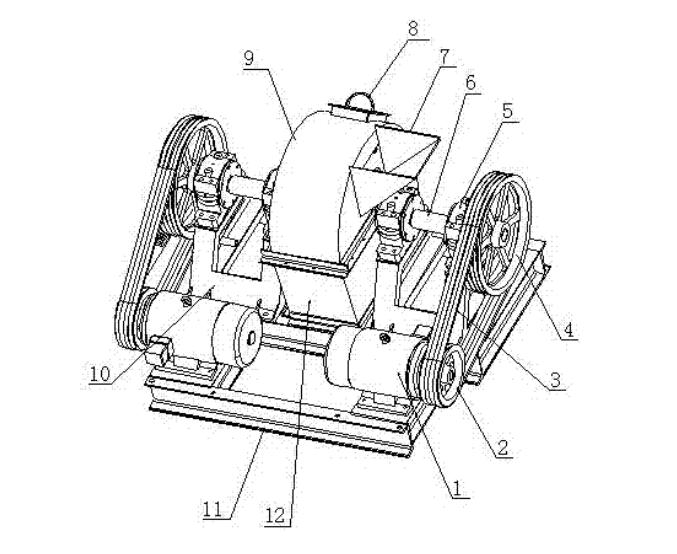

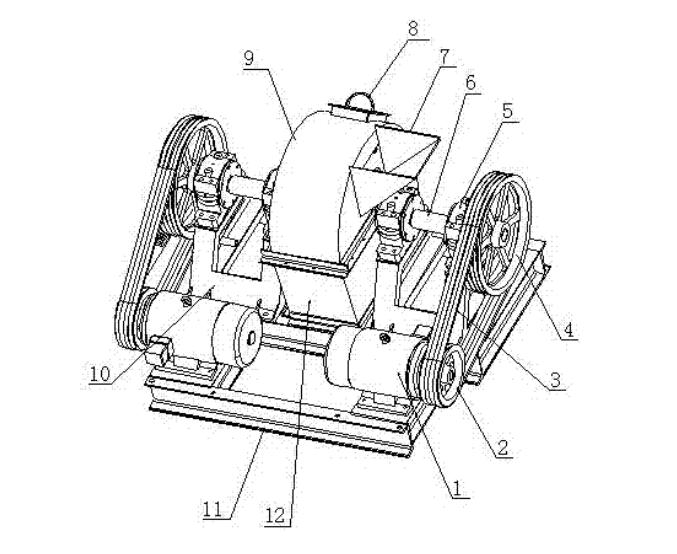

Common crushing and grinding materials mainly use extrusion, splitting, breaking or zigzag, grinding, impact and other methods to crush the materials to the required particle size. -General crushing equipment is often based on one method, with one or two other methods as auxiliary crushing materials. The squirrel cage crusher belongs to the impact crushing mode. The impact force acts on the material instantaneously, and the material is destroyed rapidly. Figure 1 is the general layout of the squirrel cage crusher, which is composed of inner cage, outer cage, feed hopper, shell, pulley, pulley, motor, bracket and other main parts.

Squirrel cage crusher

2. Improvement direction of squirrel cage crusher

Jingjiang Weineng Machinery Manufacturing Co., Ltd. has the advantages of simple production, reliable operation and large crushing ratio. The main defects are high operation speed, high operation noise and simple abrasion of the striking stick. Due to the selection of impact crushing method, the materials are easily damaged, which is the common fault of the selection of impact crushing method. With the in-depth study of crushing mechanism and the improvement of processing technology, some defects can be overcome gradually.

(1) Selecting frequency conversion speed regulation skills to adjust the speed can reduce the degree of over damage, make the machine in a better working state, and satisfy different particle size requirements together.

(2) The application of surfacing welding technique in the manufacture of the striking stick and the modification of the striking stick can obtain better anti-wear effect. For example, the service life of the striking stick can be greatly extended by using tungsten electrode surfacing welding.

(3) The wet method can reduce the noise and the degree of over damage obviously.

(4) The vibration and noise can be reduced by improving the level of production technology, reducing the unbalanced mass and selecting sound insulation and vibration isolation skills.