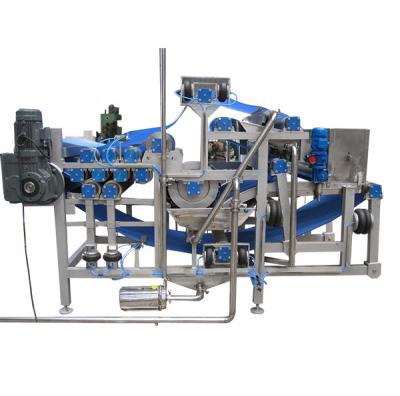

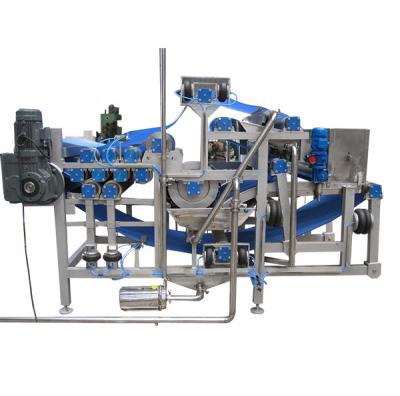

Working principle of belt Juicer

Time:2021-04-07 09:12 Browse:277

Working principle of belt Juicer

Firstly, the sludge and flocculant are mixed and flocculated into a cluster, and then through gravity dehydration, wedge dehydration, low-pressure dehydration, medium pressure dehydration and high-pressure dehydration, the sludge moisture is gradually reduced and the solid matter is discharged. This is the working principle of a new type of annular sludge dehydrator designed according to the characteristics of sludge dewatering.

The adjusted sludge enters the gravity dewatering zone of belt sludge. Under the combined action of distribution mechanism and dredging mechanism, the filter belt moves forward, and the interstitial water of sludge is removed under the action of gravity.

When the sludge enters the end of the gravity dewatering area through the filter material belt, it enters the wedge dewatering area of the belt sludge through the turnover mechanism. In the wedge dewatering area, the wedge pressure formed by two filter belts is used to preload the sludge to further remove the interstitial water.

The sludge dehydrated by gravity and wedge pressure enters into the low pressure area and high pressure area. The pressure zone consists of low pressure multi hole roll and high pressure roll. The filter belt is wrapped in the sludge and runs on the surface of the roller. As the diameter of the pressure roller increases from large to small, the pressure exerted by the filter belt on the sludge increases from small to large, which is consistent with the dewatering characteristics of the sludge.

After being pressed and dehydrated, the filter cake is solid and can be scraped off and discharged by a sludge discharging machine. In addition to the frame, the driving device drives the two filter elements to move continuously. The tensioning device is responsible for tightening the filter elements to form mud pressing force. The cleaning device is responsible for cleaning the residual slag on the filter element belt to ensure the stability of the filter element. The automatic deviation correction device is responsible for ensuring that the axial deviation of the filter belt is automatically corrected in the operation process. The function of the filtrate plate is to collect the filtrate produced by press dehydration. The roller system is composed of pressure roller, drive roller, tension roller, rectifying roller, discharging roller and guide roller, which supports the filter belt and makes the filter belt repeat various functions repeatedly.